Key points for selecting damping slides

Appearance: The surface treatment of the product must be meticulous, carefully checking for signs of rust.

Quality and Guarantee Services: Check the quality, manufacturer, and guarantee services of the damping slide rail.

Material and thickness: Check the material and thickness used for the damping slide rail. The thickness of the material is usually around 1.2mm and 1.5mm, and most materials are cold-rolled steel plates or stainless steel. If the usage location is a damp place such as a bathroom cabinet, it is best not to use stainless steel slides. It is recommended to use cold-rolled steel plates.

Smoothness and structure: Fix the fixed rail of the slide rail and tilt it 45 degrees to see if it can slide to the end. If it can slide, it means that the smoothness of this slide rail is excellent. Then pull the slide rail to its limit, hold the slide rail with one hand and the movable rail with the other hand, and shake it freely to see if the slide rail is sturdy. Pay attention to choosing a smaller slide rail for testing.

Brand: It is essential to choose a well-known and well-known brand to ensure comprehensive support from production to after-sales service, avoiding the risk of losing out on small gains by choosing miscellaneous sliding rails.

Pull out force: Use your hand to push and pull the concealed damping slide to see if it needs to be pulled out with a lot of force. Many immature manufacturers are afraid that the sliding rail may not have enough force when the drawer is closed, so they increase the force of the spring but cannot handle the lightness when pulling out, resulting in a large force when pulling out, which is an immature manifestation.

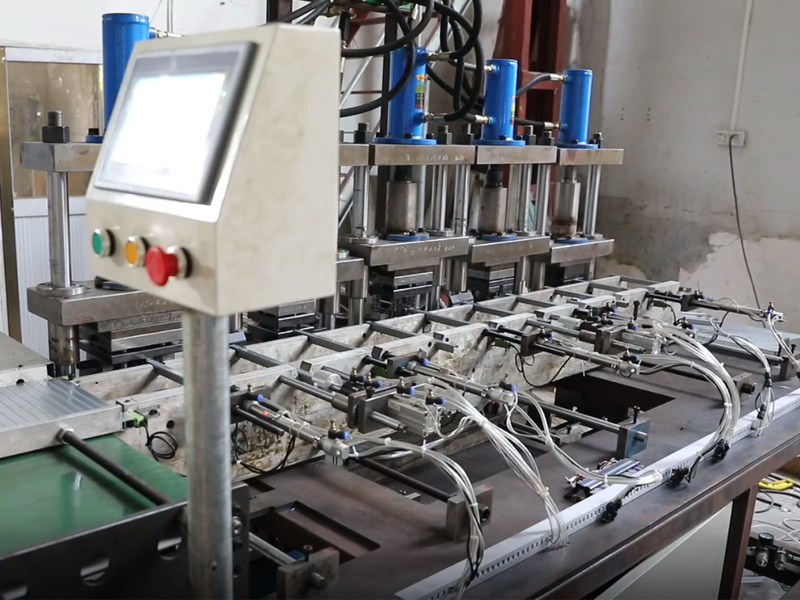

Closing time: Use your hand to push and pull the concealed damping slide, and close it for about 1.2 seconds from the moment the slide produces a damping effect until it finally closes. If it is too fast, it will produce a collision sound of the drawer slide, and if it is too slow, it may cause the drawer to not close tightly after long-term use. Generally speaking, hydraulic buffers for damping slides are easier to control the closing time, while pneumatic buffers are more difficult to control.

Whether it sways: The sliding rail installed on the drawer should not sway too much, otherwise it may cause the hidden damping rail's damping rod buffer to be unable to be carried out, ultimately leading to the disappearance of this high-end function.

Durability: You can check if you have obtained a certificate from SGS or other inspection agencies, or have the slide rail run 50000 times without damage under a load of 25 kilograms to test its durability.

TAG:

Related Posts

Key points for choosing hinges